ADA Compliant Doors and Hardware Issues

Click here to view full article

ADA Compliant Doors Survey finds commercial door hardware companies understand ADA and are designing properly for compliance

By Tim Vander Heiden

July 26, 2015, marked the 25th anniversary of the Americans with Disabilities Act (ADA), and we wanted to know what issues remain, if any, for the door hardware industry 25 years after the introduction of this expansive civil rights law. What’s the state of ADA compliant doors today?

We asked this question to more than 700 ADA consultant specialists throughout the U.S. Here’s what they had to say.

Progress…But There’s Still Work to Do

It appears that some of the problems that existed in 1990 with accessible doors and hardware still exist today. However, for the most part, door hardware companies understand ADA and are designing and specifying compliant hardware for the commercial marketplace. That said, there is still a need for innovation and improvement in some areas. Among the multitude of responses we gathered, common concerns emerged, along with some interesting and identifiable trends.

*….One of the areas where improper ADA door hardware is most apparent is in existing facilities. Mark Felling of Broadened Horizons, Inc. of Minnesota states, “I run across doors with two- or even three-inch thresholds weekly, especially with small businesses that think it is not a big deal or that their facility is accessible because [the step into the facility] is not a full-size step. But in reality, they are actually in violation of the ADA and are keeping potential customers out. I cannot count how many times I have been told [incorrectly] that they are grandfathered or are too small for the ADA to apply to them.”

We found this sentiment common among the responses from the group of consultants we polled. While the professionals in this industry understand that there is no “grandfather” clause that allows for non-compliance of ADA for any business, it is nonetheless a common held belief by many business owners that they are somehow exempt from ADA compliance at their doors. This has resulted in the annual filing of thousands of ADA litigation cases throughout the United States, putting business owners at serious risk of monetary losses.

Chris Taylor of ADA Compliance Consultants of California explains:

“Typical litigation will range any-where from $4,000 to $30,000, prior to any mitigation efforts for barrier removal. Civil penalties may run as high as $55,000 for a first violation or $110,000 for a subsequent violation.”

For large companies, these fines may be more annoying than punitive, but for smaller companies, they can add up quickly. Even for larger operations, the cumulative effect of multiple violations can be damaging. And ignorance of the law is never considered a reasonable excuse. Dennis Hytinen, President of CASp Solutions in California, states,

“Many of our clients rush to the big box stores to buy their doorknobs, only to find out that the package that says ‘ADA Compliant’ doesn’t actually meet the state regulations. I see lawsuits weekly against property owners and tenants over access, and soon I think some of the blame will be shifted to designers, contractors, suppliers and manufacturers.”

Many of the ADA consultant specialists we surveyed are involved in everyday ADA litigation and provide expert testimony at federal and state trial courts. The complexity of code interpretation has created an entire new industry of inspection professionals who are hired to interpret various complex code regulations.

Naturally, the type of facility, when it was constructed, and its use are just some of the considerations when applying the proper access laws and regulations. Additionally, some state building codes can be more restrictive than ADA on the national level.

According to Mike Miyaki, CASp, of Kim R Blackseth Interests, Inc. of California,

“We have done thousands of site surveys for commercial and

retail facilities. The main issues we find with existing door entrances are hardware (no grasping, pinching or twisting of the wrist is permitted), landings (slope issues at either the push side or pull side of the entry door), thresholds (greater than 1/2″ high, beveled) and door stops (or kick stops mounted on the bottom of the door).”

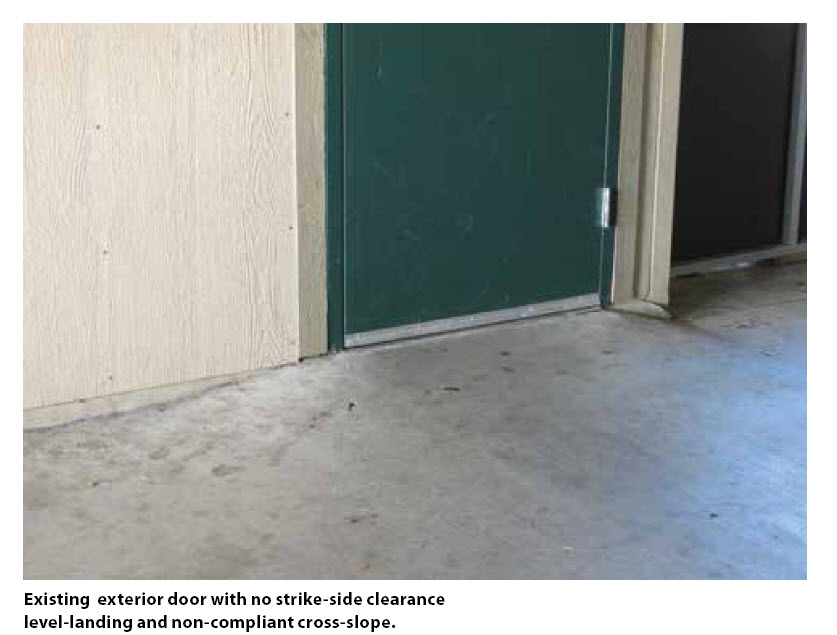

This is consistent with the responses to our survey. The most common violations listed were door threshold height issues, proper strike-side clearance, door pressure and door clearances.

Thresholds and Changes in Elevation for ADA Compliant Doors

According to Dennis Hytinen,

“Abrupt changes in elevation at thresholds and out-of-level door landings are present in 80 percent of the commercial properties we survey.”

This is a violation of ADA regulations. When it comes to changes in the level of the floor surface, ADA 2010 Standards 303.2 and 303.3 state:

“Changes in level of ¼ inch (6.4 mm) high maximum shall be permitted to be vertical.” In addition, “Changes in level between ¼ inch (6.4 mm) high minimum and ½ inch (13 mm) high maximum shall be beveled with a slope not steeper than 1:2.”

However, 404.2.5 does allow for

“existing or altered thresholds 3/4 inch (19 mm) high maximum that have a beveled edge on each side with a slope not steeper than 1:2.”

Often contractors are required to purchase aftermarket products such as modular ramps or landings to bring new and existing door products into compliance. In the new 2010 ADA standards, sliding glass doors are required to meet the ½” vertical rise requirement, whereas under the old standards, a ¾” threshold height was allowable.

Although there are some ADA-compliant sliding doors that are sold as a complete system by the manufacturer, very few sliding glass door manufacturers produce sliding doors with any substantial door pressure (DP) rating that meet the current ADA threshold requirement.

Door Hardware – ADA Compliant Doors for people with disabilities improve.

Door hardware can be problematic for individuals with disabilities. Marcela Abadi Rhoads, AIA, RAS, from Abadi Accessibility in Texas, states,

“Pocket doors typically have a hardware that is recessed into the door and operated by using a thumb or tip of the finger to engage. Persons with disabilities might have a hard time engaging this type of operation. The ADA requires that no tight grasping will be utilized to open the door.”

Another common violation occurs at unisex restrooms, which are required to provide a lock that shows when the restroom is occupied. ADA 2010 Standard 213.2.1 Unisex (Single-Use or Family) Toilet and Unisex Bathing Rooms states that

“toilet doors to unisex toilet rooms and unisex bathing rooms shall have privacy latches.”

Pocket doors and restroom locks aren’t the only problem. Mike Boga of Disability Access Consultants, LLC, of Florida says,

“We provide ADA surveys for cities, schools and municipalities, and we continuously see where doors are out of compliance as a result of the placement of door stops, which violate the push-side clearance for the smooth surface requirement of 10 inches from the finished floor.”

Boga is referring to ADA 2010 Standard 404.2.10 Door and Gate Surfaces, which states:

“Swinging door and gate surfaces within 10 inches (255 mm) of the finish floor or ground measured vertically shall have a smooth surface on the push side extending the full width of the door or gate.”

This allows people to move wheelchairs or other assisting equipment freely through an opening with-out the possibility of hitting hardware that may be protruding from the door.

Maneuvering Clearances for ADA Compliant Doors

This leads directly into a discussion of maneuvering clearances. A common ADA violation is the absence of a maneuvering clearance area beyond the latch side of the door. ADA 2010 Standard 404.2.4 Maneuvering Clearance states that doors should have a clear area for wheelchair approach, and this is required at both manual and swinging doors. The area varies, depending upon the type of push or pull configuration, from 42” at the minimum to 60”, which is often the typical standard configuration for a level landing.

Ron Urzedowski of Riverside CASp LLC, states that in many places,

“Level clear space/maneuvering space at entries have slopes that exceed the maximum allowable grade.”

This point was echoed by several of our survey respondents, indicating that maneuvering clearance areas are still a major concern for many commercial applications.

Kaylan M. Dunlap, LPTA, CASp, Evan Terry Associates in Alabama, says,

“We see many businesses and facilities that have not addressed issues that are…easily addressed with not too much cost associated. Some that are easily addressed are removing movable items such as a planter, trash can or merchandise display that obstructs door maneuvering clearance so that someone using a mobility device (wheelchair, scooter, walker, crutches, cane, etc.) has room to approach the door and maneuver around to get it open and then to get through it.”

Pull Clearance and Closing Speed

Maneuvering clearance isn’t the only clearance issue for individuals with disabilities. Jill S. Johanning, AIA, Licensed Architect Access Design/Alpha One of Maine, states,

“Door pull clearances are one of the most typical problems I find in buildings for not providing access to all. That 18 inches of clear space is very attractive to locate furniture, to let landscaping overgrow, and especially to put trash-cans. One of the programs in Maine assists people with disabilities find homes in the community, and because of the existing threshold and weight of the exterior door, it is hard for individuals to access their home. One of the most requested accommodations through this program is keyless entry at the door to help provide more independence to the residences.”

We also discovered that there is still the belief by industry experts that door closing speed is three seconds, but in the new 2010 ADA standards, it is actually five seconds. ADA 2010 Standard 404.2.8.1 Door Closers and Gate Closers says,

“Door closers and gate closers shall be adjusted so that from an open position of 90 degrees, the time required to move the door to a position of 12 degrees from the latch is five seconds minimum.”

To meet this requirement, the door closer must have an adjust-able closing speed (sweep speed).

Conflicts to Consider

ADA 2010 Standard 404.2.7 Door and Gate Hardware states that

“Handles, pulls, latches, locks, and other operable parts on doors and gates shall comply with 309.4

. Operable parts of such hardware shall be 34 inches (865 mm) minimum and 48 inches (1220 mm) maximum above the finish floor or ground.”

However, if glazing is required to be a maximum of 43” above the finished floor, a conflict can occur. ADA 2010 Standard 404.2.11 Vision Lights states,

“Doors, gates, and side lights adjacent to doors or gates, containing one or more glazing panels that permit viewing through the panels shall have the bottom of at least one glazed panel located 43 inches (1090 mm) maximum above the finish floor.”

“This can present an issue with panic hardware located in front of door glazing,” says Marcela Abadi Rhoads. Both of these ADA sections—404.2.7 and 404.2.11—should be taken into consideration by designers, specifiers and door manufacturers to avoid panic hardware adjacent to glazing material.

Where We Go from Here

Five years ago, the Department of Justice revised the ADA accessibility standards; it is now referred to as the 2010 ADA Standards for Accessible Design.

On March 15, 2012, compliance with the 2010 Standards was required for new construction and alterations under Titles II and III. Over the past 25 years, the door hardware industry has responded to the regulations put forth by ADA.

As these regulations continue to evolve, the real challenge is to have compliant door hardware products for state regulations that often are more restrictive than federal ADA standards and can make product specification and local jurisdictional compliance more problematic.

However, as the aging population continues to increase, it is expected that there will be continued demand for accessible door hardware products. With thousands of ADA surveys being conducted across the U.S. on a weekly basis, there is plenty of work and product demand to be done to bring existing facilities into compliance.

TIMOTHY VANDER HEIDEN, J.D., is CEO of SafePath Products and Van Duerr Industries, Inc. He has more than 25 years of experience marketing and manufacturing products for ADA compliance, specializing in green technology for the architectural marketplace. Tim and his team can be reached at 800.497.2003, or visit www.safepathproducts.com.